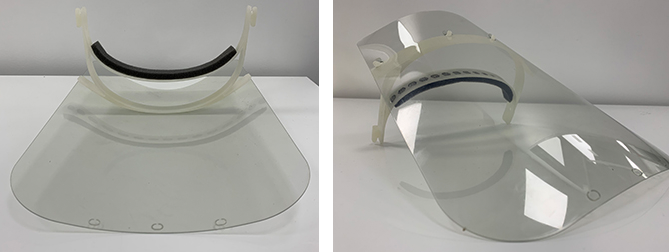

The first prototype was printed and assembled in less than 24 hours thanks to 3D printing technology and the strength of Ricoh’s supplier network

Ricoh 3D has ramped up its support to tackle the COVID-19 crisis by using its technology to produce 40,000 face shields a week for NHS workers, designed to improve comfort and offer a re-usable solution to cut long-term costs.

Ricoh 3D in the UK is in discussions with medical establishments and NHS Trusts across the UK, after working around the clock to get effective protective equipment to the frontline using the rapid prototyping capabilities of additive manufacturing.

Just 24 hours after receiving the design file, the Ricoh team had the head support 3D-printed and remaining components sourced and assembled using its supplier network. Having refined the design to enhance comfort and reduce contamination, the face shield has now been approved for production.

It is estimated in London alone more than 150,000 face guards will be used every day in the battle against COVID-19. Ricoh will upscale to full production utilising a 150-tonne injection moulding machine.

Mark Dickin, Additive Manufacturing & Moulding Specialist at Ricoh 3D, said: “Our site is uniquely set up to take a product from concept to prototype to serial production, and that is exactly what we have done here in a very short timeframe. This really is a testimony to the strength of our supplier relations and the cross-functional team who made it happen so quickly. Local suppliers for the foam, elastic strapping and visor components have come forward across our production print, design solutions and quality assurance networks. We were seeing reports of nurses’ faces being cut and bruised by their existing protective equipment. Our frontline workers are battling enough already, without having to tend to sore and swollen faces at the end of a 12-hour shift. We knew our Polypropylene material was ideally suited for the job with its flexible, lightweight, watertight and fatigue resistant nature. Given its comparable properties to injection moulding, we had no doubts that this was the right material to support the transition to full moulded production.”

Jason Pott, Lead Research Nurse for Emergency Medicine at The Royal London Hospital, added: “In our tests, staff commented on the comfort of Ricoh’s solution over existing equipment. We tested across a range of male and female staff in the emergency department with different head shapes, hairstyles and head scarves – everyone was happy with the fit. Innovations like this help staff in the NHS to remain safe while caring for those in need.”

Ricoh 3D already produces over five million mouldings per month as part of Ricoh’s toner business. Ricoh 3D has experience with medical projects. These include development of a lever-hinge mechanism for ankle-foot orthotics and involvement in revolutionary new technology which sees limbs scanned and precisely replicated using 3D printing prior to operation. Surgical instruments can also be produced using additive manufacturing and are typically used for intricate operations.