Last November, G&G revealed the process of how its wide-format cartridges were produced. The company is now following up with an article and video about its R&D process for these cartridges.

The G&G wide-format product range has been expanded to fit the growing variety of consumer demands, including outstanding stability, photographic quality and affordable costs, G&G revealed.

“When you consider all the factors that impact output, printing stability is considered as a critical one users can’t ignore,” admitted Kevin Cai, Senior Ink R&D Engineer of G&G. “Our team has been dedicated to the task to improving the stability of large- and wide-format inks and the cartridges.”

In its video, G&G reveals different R&D stages of its production process of its large- and wide-format inkjet cartridges. G&G describes the elements as follows:

Colour paste from best-in-class suppliers

As the main component of ink, colour paste plays an important base function in ink quality. The colour pastes G&G selects are imported from what it says is the best-in-class suppliers, like DuPont and Cabot, which have also been proven to be environmentally friendly with RoHS and REACH compliance.

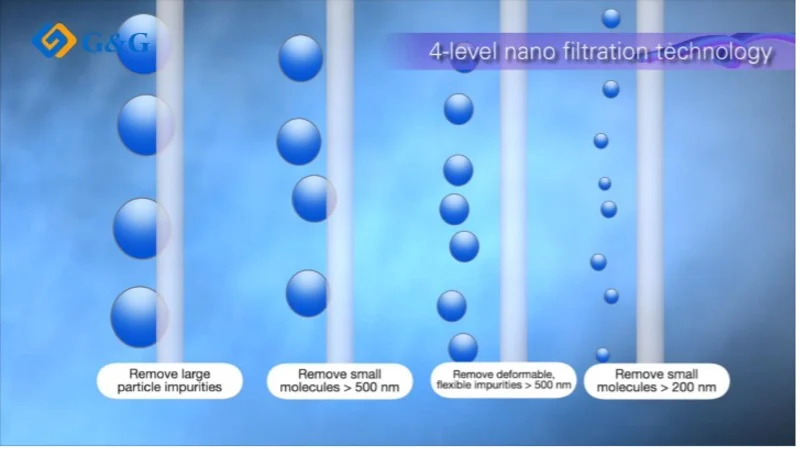

4-level nano ink filtration technology

To completely intercept the macromolecules in the ink raw materials, G&G has adopted 4-level nano filtration technologies, which will prevent the printhead from clogging.

Aqueous solvent added to improve standby performance

Aqueous solvent added to improve standby performance

Usually, the print head gets covered with ink which dries, particularly of the cartridge is not used for an extended period of time. Compatible inks tend to dry more quickly. To solve this, G&G adds moisturising materials to the ink to keep them moistened on the print head, so that it will maintain a stable state and run longer time without drying out.

Use selected resins to produce glossy printing results

During the development stage, considerable time and energy were consumed in the selection of suitable resins and to run numerous tests to guarantee their respective properties, G&G explained. This is how glossy, fast-dry, rub-resistant results are produced.

Stability in wide-format cartridge design

G&G made 3D measurement and fine adjustments to the structure of the cartridges, which enables a stable supply of ink and perfect compatibility with the machine. Engineers also run installation force tests to ensure the end users can install the cartridges effortlessly.