This week Armor has revealed its new 3D printing filament from the company’s ABS ESD range.

Erik Henstra, Account Manager, explains that the printing filament “is a material based on ABS (acrylonitrile butadiene styrene) supplemented by additives to provide anti-electrostatic discharge protection.”

Armor has developed two different formulations – ABS ESD-R and ABS ESD-S.

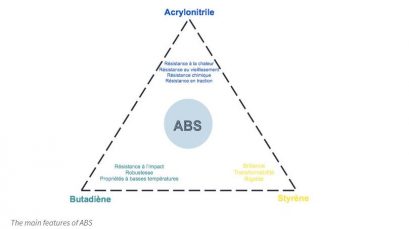

The company explains that ABS is “a thermoplastic currently widely used in additive manufacturing” which is “acknowledged for its resistance to impact, heat and ageing, and also for its rigidity and robustness.”

3D printers which are compatible with ABS “must have a heated plate as it easily becomes unstuck”, shrinking when it comes into contact with air.

Armor goes on to elaborate, “The ABS ESD-R offers greater rigidity and cannot be coloured, it is available in black. It provides permanent protection against electrostatic discharge without losing effectiveness over time.

The ABS ESD-S is natural, enabling it to be coloured. It has better impact resistance and similarly offers permanent protection against discharge, regardless of how much time has passed.”

Armor also laid out the printing parameters for the new 3D printing filament.

For ABS ESD-S, the extrusion temperature is 260 degrees Celsius, the plate temperature is 100 degrees Celsius and the print speed is 40 mm/s.

For ABS ESD-R, the parameters are the same.

However, for ABS Classique, the extrusion temperature is 220 degrees Celsius, the plate temperature is 90 degrees Celsius, and the print speed is 40-80 mm/s.

For more information go to www.kimyra.fr. Kimya is the 3D printing trademark of the Armor Group.